Explosion Vent Panel Device - DVPNL

Key words:

Explosion Vent Panel Device - DVPNL

Classification:

Case Details

Product Introduction:

The conventional explosion venting solution for energy storage cabinets/boxes involves installing a venting panel on the top of the box. The conventional energy storage venting panel DVPU is designed to withstand various harsh conditions such as rain, snow, hail, and extreme temperatures due to long-term outdoor exposure. Therefore, an insulation layer and climate protection cover are added outside the venting panel. However, after installation, the external protective layer protrudes from the top of the box, posing a risk of damage during transportation and on-site arrangement, which increases the owner's additional expenses for replacing and maintaining the venting panel.

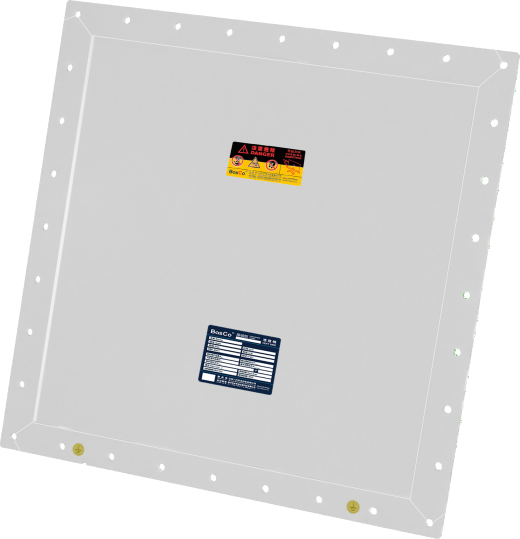

Compared to the conventional energy storage venting panel DVPU, the DVPN venting panel innovatively places the insulation module below the venting panel (i.e., between the venting panel and the interior of the cabinet). This design significantly reduces the protrusion height after the installation of the venting panel, decreasing it by approximately 40mm compared to the conventional energy storage venting panel DVPU.

Technical Features:

- Fixed with bolts to the cabinet, easy to install and maintain.

- Equipped with insulation cotton, maintaining the same insulation performance as the cabinet.

Technical Parameters:

Product Name |

DVPNL |

Operating Environment Temperature |

-40℃ ~ +60℃ |

Static Opening Pressure |

0.01 MPa ± 25% @22℃ |

Vacuum/Back Pressure |

-0.003 MPa |

IP Rating |

IP66 |

Working Pressure |

0.1 MPa(A)±2% |

Product Configuration:

- Single-layer SUS 304

- Silicone Foam UL94 V0 (-55℃ ~ +200℃)

- Includes flange + silicone foam

- Thermal Conductivity of Insulation Cotton:

- ≤0.034 W/(m·K) (0℃)

- ≤0.039 W/(m·K) (40℃)

- No water retention and anti-seismic design

Selection Specifications:

Nominal Diameter (mm) |

External Dimensions (mm) |

Discharge Area (mm2) |

230×305 |

330×405 |

68000 |

305×457 |

405×557 |

136000 |

400×400 |

500×500 |

160000 |

400×700 |

500×800 |

280000 |

457×610 |

557×710 |

274000 |

378×810 |

450×882 |

300000 |

457×762 |

557×862 |

341000 |

457×915 |

557×1015 |

414000 |

610×610 |

710×710 |

367000 |

610×762 |

710×862 |

459000 |

610×915 |

710×1015 |

552000 |

Applicable Standards:

- EN14994

- EN14797

- NFPA68

Venting Panel Device Selection Guide:

First, select the category of venting panel products, and choose between upper insulation or lower insulation based on your needs.

The upper insulation venting panel has a thickness direction that is higher than the installation interface, providing superior and reliable environmental weather resistance for long-term outdoor use. The lower insulation venting panel has a thickness direction that is lower than the installation interface, saving space above the cabinet for easier transportation and placement.

Next, provide the corresponding parameters and select the size of the venting panel through compliant calculations.

Product Testing:

Product Certification:

Application Scenarios

Project