Automatic Fire Detection and Extinguishing System

Classification:

Details Introduction

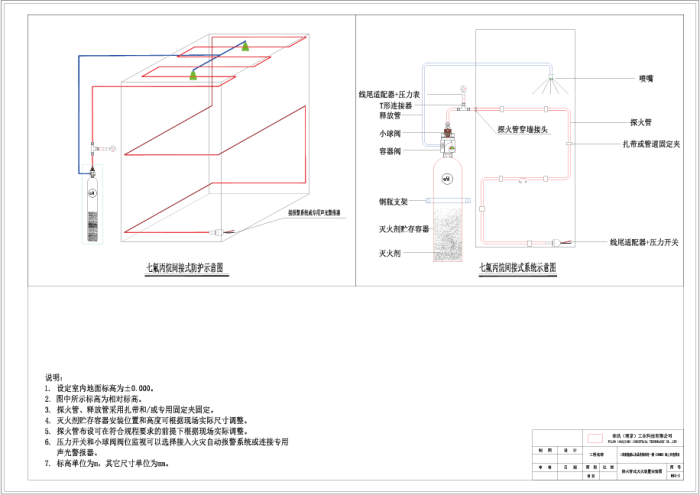

The working principle of the fire detection device consists of a pressure vessel containing extinguishing agent, specialized container valves, and fire detection tubes that can release the extinguishing agent. The fire detection tubes are arranged along potential fire hazard points, and under pressurized conditions, they detect using multiple detection points (linear). When exposed to open flames or temperature shocks, the fire detection tube will burst at the hot spot, causing the valve to actuate after the tube loses pressure, releasing the extinguishing agent through the release pipe to the nozzle, and transmitting the fire signal.

The fire detection tube is a type of high polymer material that integrates flame retardancy, flexibility, and temperature sensitivity, capable of long-term leak resistance, with a maximum leakage rate of 10-5 mbar*l/s/m. It is a linear hose that is not affected by dust, oil stains, or electromagnetic fields.

The system operates independently, requiring no external power supply and is not affected by power outages.

The unique integrated valve design features a built-in ball valve, preventing damage to the ball valve and reducing the possibility of leakage.

Quick-connect fittings with a double sealing ring design ensure good sealing.

Highly integrated electromagnetic valve combination design provides customized solutions for clients, meeting the needs of different industries and application scenarios, with simple design and installation, and low maintenance costs.

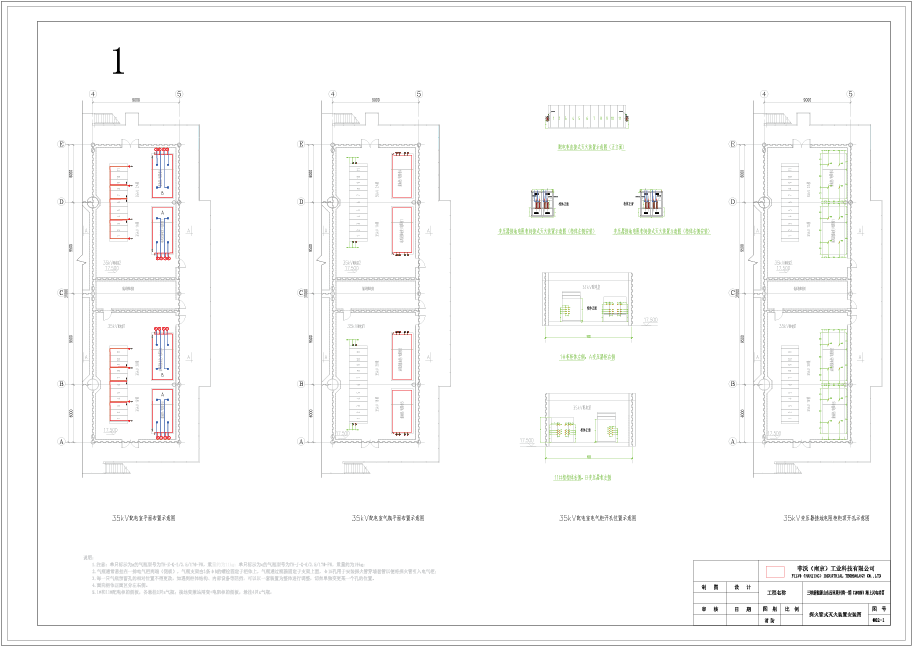

Schematic diagram of fire detection tube layout.

Design drawing example.